All parts of the engine are so closely related in their operation that discus¬sion of repair and adjustment of a single part cannot be explained without simultaneous consideration of related units. Causes of and remedies for en¬gine troubles, therefore, can best be discussed in reference to the following six groups of engine parts.

- Connecting-rod assembly (including connecting rod, connecting-rod bear¬ings, wristpin and bearings, piston, cylinder wall, and piston rings)

- Crankshaft, main bearings, flywheel and crankshaft gear or sprocket

- Valve mechanism (including valves, valve guides, springs, seats and in-serts, valve lifters and adjusting screws; -rocker arms and push rods for overhead valves; hydraulic valve lifters; camshaft, camshaft bearings, and camshaft gear or sprocket)

- Cylinder head and cylinder block

- Oil pan

- Ignition system, cooling system, fuel system, lubricating system, starting And generator systems.

Connecting-rod bearings are loose when too much clearance occurs be-tween them and the crankpin on the crankshaft. When this condition exists, there will be a light-heavy knock. The loose bearing can usually be located by "shorting" out the spark plugs one at a time, with a wooden-handled screw driver. The shorted spark plug that lessens the knock is in the cylinder with the loose connecting-rod bearing. A loose bearing can cause the crankpin to wear more rapidly to an "out-of-round" or "egg" shape since each time it knocks there is added wear and strain on the same points of the crankpin with each revolution of the crankshaft. Another result of a loose bearing is that the greater clearance between crankpin and bearing is filled with an excess of oil from the oil line, which is splashed from the sides of the bearing up on the cylinder wall. This excess oil is too much for the piston rings to keep from getting up into the combustion chamber, where it is burned with the gasoline and wasted. A worn or loose connecting-rod bearing is caused by inadequate lubrication , resulting from a lack of oil in the oil pan; oil pump supplying insufficient oil because its operation is faulty or because the oil lines are clogged oil dipper; or by an out-of-round crankpin or connecting-rod bore; by a bent or twisted connecting rod; by a bearing fitted too tight to the crankpin; or by oil of unsuitable viscosity. If not repaired promptly, loose connecting-rod bearings may crack and fall out, seriously damaging the crankshaft because the exposed steel bore of the connecting rod would then score or mark the crank¬pin. A bearing that gets no oil at all will "burn out" in a few miles of driving, the friction causing the babbitt-bearing lining to become so hot that it will melt away into the oil pan.

A connecting rod with the spun type of bearing may be adjusted to the specified clearance by inserting or taking out an equal number of shims from each side of the bearing.

The insert or removable type of bearing has no adjustment. When this bearing wears, it is simply replaced by another of standard size if the crankpin is still true and of original size. Often, when the crankpin is worn or out of round and or tapered, it is advisable to regrind the crankpin to a smaller size and install a new undersize bearing insert. Unlike the spun type, inserttype bearings may be replaced without removing the connecting rod. Under size bearings are manufactured in stock sizes for convenience. To cut costs taper shim bearing adjusters are also available.

In early-model Ford V-8 engines one bearing insert assembly is used for two connecting rods on one crankpin. The bearing turns in the rod bores and on the crankpin. Babbitt-bearing metal is on each side of the insert, and there is clearance between the bearing and the connecting-rod bores and the bearing and the crankpin.

Measuring Bearing Clearance, There are several ways of measuring the clearance between a journal and a bearing. One is by use of an oil-pressure tank that supplies oil to the engine oil line to duplicate the engine lubricating system. This can be done only after the oil pan is removed, and in a limited number of engines. The rate at which the oil escapes between the bearing and the journal is a measure of the clearance. Bearings that are too tight allow little or no oil to escape; loose bearings allow the oil to leak out rapidly. This method also helps to locate a dogged oil line.

Another convenient and accurate way is by use of Plastigage manufactured by the Perfect Circle Corporation, Hagerstown, Indiana. This string- like plastic is placed along the full width of the bearing or shell so that when the connecting-rod or main-bearing cap is installed, the plastic is compressed between the bearing and the journal. (Bearing and journal should be oil-free before this is done. The cap is then tightened to manufacturer's specifications by means of a torque wrench. (The use of a torque wrench will be explained later.) The smaller the clearance between the journal and the bearing, the more the plastic will be spread out and flattened by the tightened cap. A scale, supplied with the Plasticine, is then held along-side it when the cap is removed ( see Fig. 5-1B) and by a comparison of

widths, the clearance is determined. Plastigage is manufactured in several clearance ranges. The one pictured in Fig. 5-1 has a range of 0.001-0.003 in Another method in common use is to place a piece of brass shim stock or oiled paper about 1/2 in. wide and % to 1 in. long with a thickness equal to the desired clearance ( gen e rally between 0.005 and 0.002 in.) between the journal and the bearing and tighten the cap to the specified torque. By noting the drag produced when the flywheel is turned a little,size of the shim and the amount of drag are generally given by the manu facturer.) Some service procedures recommend measuring the diameter of the jour nal and the thickness of the bearing insert with a micrometer and comparing their dimensions with the standard to determine the clearance.

A connecting rod with the spun type of bearing may be adjusted to the specified clearance by inserting or taking out an equal number of shims from each side of the bearing.

The insert or removable type of bearing has no adjustment. When this bearing wears, it is simply replaced by another of standard size if the crankpin is still true and of original size. Often, when the crankpin is worn or out of round and or tapered, it is advisable to regrind the crankpin to a smaller size and install a new undersize bearing insert. Unlike the spun type, inserttype bearings may be replaced without removing the connecting rod. Under size bearings are manufactured in stock sizes for convenience. To cut costs taper shim bearing adjusters are also available.

In early-model Ford V-8 engines one bearing insert assembly is used for two connecting rods on one crankpin. The bearing turns in the rod bores and on the crankpin. Babbitt-bearing metal is on each side of the insert, and there is clearance between the bearing and the connecting-rod bores and the bearing and the crankpin.

Measuring Bearing Clearance, There are several ways of measuring the clearance between a journal and a bearing. One is by use of an oil-pressure tank that supplies oil to the engine oil line to duplicate the engine lubricating system. This can be done only after the oil pan is removed, and in a limited number of engines. The rate at which the oil escapes between the bearing and the journal is a measure of the clearance. Bearings that are too tight allow little or no oil to escape; loose bearings allow the oil to leak out rapidly. This method also helps to locate a dogged oil line.

Another convenient and accurate way is by use of Plastigage manufactured by the Perfect Circle Corporation, Hagerstown, Indiana. This string- like plastic is placed along the full width of the bearing or shell so that when the connecting-rod or main-bearing cap is installed, the plastic is compressed between the bearing and the journal. (Bearing and journal should be oil-free before this is done. The cap is then tightened to manufacturer's specifications by means of a torque wrench. (The use of a torque wrench will be explained later.) The smaller the clearance between the journal and the bearing, the more the plastic will be spread out and flattened by the tightened cap. A scale, supplied with the Plasticine, is then held along-side it when the cap is removed ( see Fig. 5-1B) and by a comparison of

widths, the clearance is determined. Plastigage is manufactured in several clearance ranges. The one pictured in Fig. 5-1 has a range of 0.001-0.003 in Another method in common use is to place a piece of brass shim stock or oiled paper about 1/2 in. wide and % to 1 in. long with a thickness equal to the desired clearance ( gen e rally between 0.005 and 0.002 in.) between the journal and the bearing and tighten the cap to the specified torque. By noting the drag produced when the flywheel is turned a little,size of the shim and the amount of drag are generally given by the manu facturer.) Some service procedures recommend measuring the diameter of the jour nal and the thickness of the bearing insert with a micrometer and comparing their dimensions with the standard to determine the clearance.

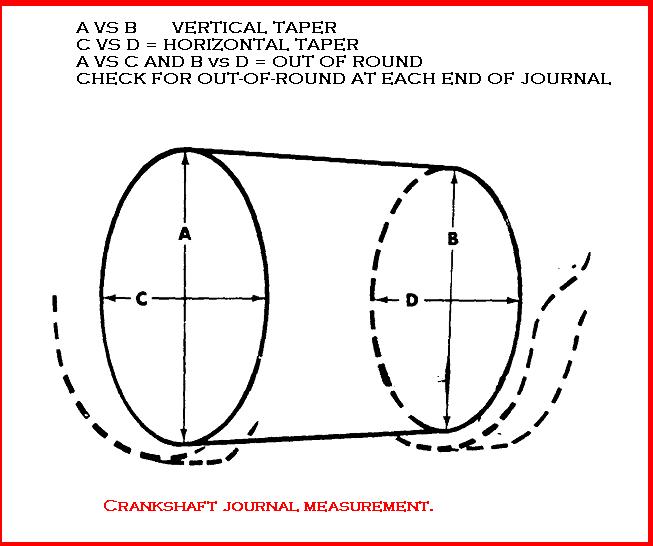

Journal. The size of a journal, the extent that it is out-of-round, and its taper are determined by measurement with a micrometer. Specially designed micrometers can be used on crankshafts that are left in the engine.

Connecting Rods. Whenever connecting rods are removed from the engine,

they should be tested for alignment. This is done in a piece of equipment called a connecting-rod aligner. See twisted rods may be straightened in the aligner with a bend

Connecting-Rod Side Clearance Connecting Rod ing iron. Bent or twisted rods will cause Crank shaft rapid bearing, cylinder, ring, piston,

and pin wear, because of their tendency to oppose the vertical travel of the pis tons in the cylinders. A connecting rod with a double bend or offset may cause the piston-pin hole to be offset from the crankpin hole bill yet be arallel to it. This double bend will cause the should be corrected in the same way. same damage as the single bend, and The out-of-roundness of the rod bore glk Connecting-Rod Bearing Cap should also be checked with a special Crankshaft Counter weight gage. Connecting-rod side clear ance.Wristpins or Piston Pins. When a piston pin wears or becomes loose in the piston and connecting rod, it causes a high-pitched sharp double-knock at each end of its stroke. It can usually be located by "shorting" out the spark plugs, one at a time. When the knock increases in intensity, it is an indication that the loose pin is in that cylinder. The sound of the knock can be confused with the knock or tap of a valve with too much clearance between it and the adjusting screw.

The only way to correct this condition is to remove the piston and con necting-rod assembly. If the piston is made of cast iron, the pin lock screw or rings which hold the pin in place may be taken out and the pin easily re moved. The bushings, whether in the piston or in the connecting rod, may be pressed out, and new standard-size bushings - installed. The bushings are then reamed or honed to proper fit for a new standard-size piston pin. All pins,whether fitted to bushings or direct to aluminum pistons, have clearances between 0.0001 and 0.0009 in.

When steel alloy pistons are used, the piston pin is fitted in exactly the same way, although bushings are not used in these pistons. An oversize pir may be used by reaming the connecting-rod bushings or the steel piston bosse to the necessary size.